Building a Sustainable Future with Low Carbon Aircrete

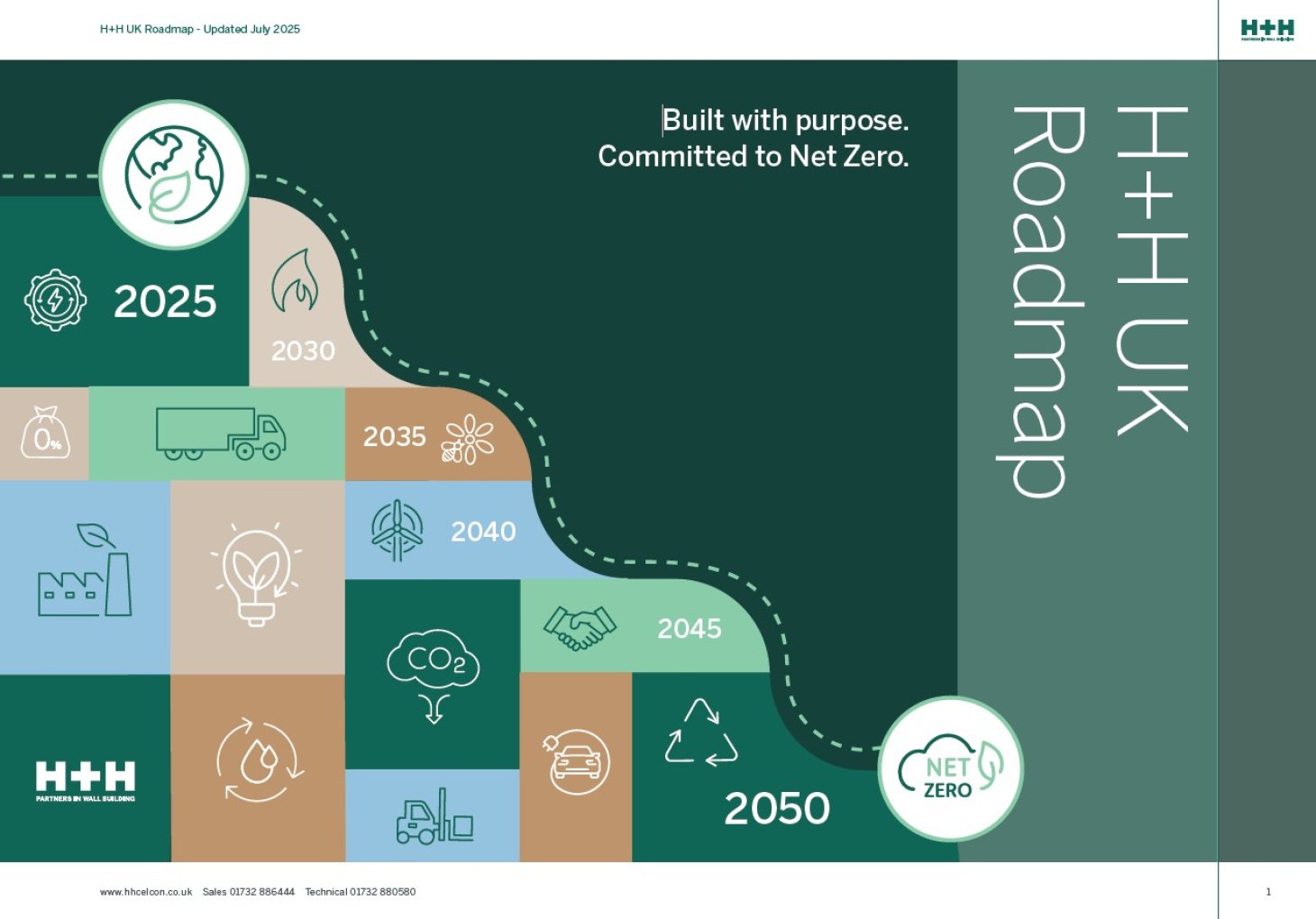

At H+H UK, our mission is to deliver zero carbon aircrete building products that support a sustainable built environment. By reducing emissions in our manufacturing processes and maximising the positive impact of aircrete in use, we are committed to achieving net zero emissions by 2050.

Why Whole-Life Carbon Matters

Understanding the environmental footprint of construction materials requires a cradle-to-grave approach. In 2020, H+H International conducted a detailed Lifecycle Assessment (LCA) of aircrete to measure emissions at every stage:

- Manufacturing

- Transport and logistics

- Use in buildings

- End-of-life recycling or disposal

This analysis showed that:

- Over 85% of Scope 3 emissions come from raw materials such as lime and cement.

- Local manufacturing in the UK reduces transport-related carbon emissions.

- Aircrete naturally undergoes recarbonation, capturing carbon during its use phase.

By focusing on the entire lifecycle, H+H ensures that our aircrete blocks provide real, measurable benefits for low carbon construction.

Low Carbon Manufacturing: Our 2030 Targets

We are working toward carbon-neutral manufacturing by 2050, with an interim goal to cut emissions per block by 50% by 2030 (Scopes 1–3, based on 2019 levels).

Progress so far:

- 100% renewable electricity powers the production of Celcon Blocks.

- Our on-site wind turbine supplied 17% of UK electricity needs in 2024.

- LED upgrades saved 200,000 kWh annually.

- Hydrogen-ready boilers cut gas emissions by ~600 tCO₂ each year and reduced NOx by 30%.

- A greener fleet: 94% of cars and vans are hybrid or electric, while forklifts and trucks are switching to EV and HVO fuels.

These initiatives put us at the forefront of sustainable building material manufacturing.

Tackling Scope 3 Emissions Across the Supply Chain

Decarbonising construction requires collaboration across the value chain. H+H is working with suppliers to reduce upstream emissions from lime and cement, which account for the majority of embodied carbon.

Supplier initiatives include:

- Lime production: Green hydrogen pilot projects with the goal of becoming net negative by 2040.

- Cement production: Use of alternative fuels, including biomass, aligned with Science Based Targets (SBTi).

We are also improving resource efficiency in other areas:

- Zero waste to landfill since 2022, with 100% of aircrete waste recycled.

- 60% water recycling across operations.

- Packaging with 30%+ recycled content, FSC® certified pallets, and material reductions of ~30%.

Aircrete for Low Carbon Homes

Aircrete is more than a low carbon construction material—it actively supports the creation of energy-efficient homes.

- Thermal efficiency: Aircrete’s insulation properties reduce operational energy demand, making it ideal for Passivhaus and fabric-first design.

- Recarbonation effect: Cement-based products absorb CO₂ over time, effectively turning buildings into carbon sinks.

- Future potential: With sustainable manufacturing and in-use benefits combined, aircrete could evolve into a carbon-negative building material.

Environmental Product Declarations (EPDs) for Transparency

At H+H UK, transparency and accountability are central to our sustainability commitments. We now have four Environmental Product Declarations (EPDs) published for our products, providing independently verified Life Cycle Assessments (LCAs) that demonstrate the environmental impact of our materials across their entire lifespan.

- Over 50% of upfront embodied carbon (A1–A3) is recaptured during the building’s in-use phase through the natural re-carbonation process.

- Aircrete’s durability means it continues to deliver carbon benefits over its long lifespan.

- All EPDs are third-party verified and compliant with EN 15804+A2 standards.

- True comparison between materials must consider Whole Life Carbon, including in-use and end-of-life stages..

What’s Next for H+H UK

Our zero carbon roadmap continues with initiatives focused on:

- Hydrogen-ready plants and participation in hydrogen innovation projects.

- Explore alternative transport fuels across our logistics network.

- Improving resource efficiency by lowering water use and sourcing eco-friendly raw materials.

- Supporting biodiversity and nature-positive outcomes at manufacturing sites.