How do aerated blocks, like Celcon Blocks, get their structure and where can they be used?

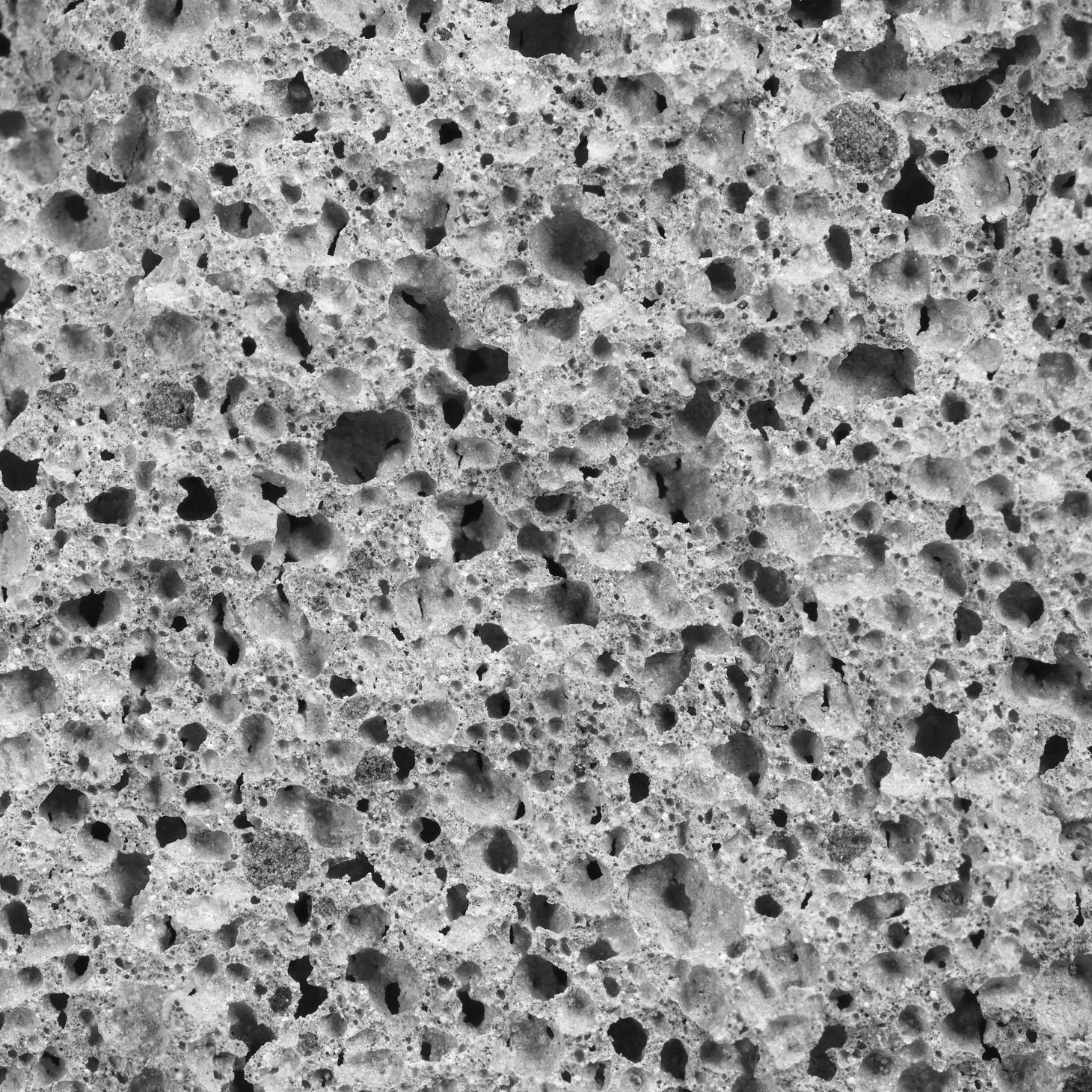

Aerated blocks, also known as aircrete or Autoclaved Aerated Concrete (AAC), are precision-engineered, lightweight concrete blocks made from cement, lime, water, pulverised fuel ash (PFA) and aluminium. During production, the aluminium reacts with the other ingredients, creating microscopic air pockets throughout the material. These air pockets give aerated blocks their distinctive light weight and excellent thermal insulation properties.

H+H manufactures aerated blocks in the UK under the Celcon Blocks brand, using locally and European sourced raw materials.

What are aerated blocks used for?

Aerated blocks are widely used for constructing walls, floors and foundations in low-rise buildings such as houses, schools, and offices.

Aerated blocks can be used to construct:

- Cavity Walls (internal and external leaves)

- Solid Walls

- Partition Walls and Separating Walls

- Foundations (DPC level)

- Beam and Block Floors

Cavity walls

Where a single wall is constructed of two leaves of masonry with a cavity in between and where each leaf has a distinct purpose. The external leaf protects the structure from moisture penetration while the inner leaf provides the main structural support for the building. Celcon Blocks fulfil both these requirements. Celcon Blocks contribute to thermally efficient, fire-resistant external walls that help meet Building Regulations, including Part L requirements.

Solid walls

Large-format aerated blocks (minimum 200mm wide) provide a robust, single-leaf wall solution, without an air cavity. Known for its strength and durability and when combined with suitable insulation, they achieve full regulatory compliance.

Partition walls or separating walls

Internal walls in buildings can be built with aerated blocks rather than timber stud-walls to provider greater acoustic insulation in between rooms. They also provide a more solid base for hanging heavy furniture like kitchen cupboards.

Party walls built of aircrete will easily pass the requirements of Building Regulations Approved Document E. H+H aircrete has been successfully used in cavity separating – or party – walls for many years.

Foundations or below ground level (DPC)

Thanks to their strength and durability, aerated blocks are well-suited for use in foundation construction suitable for use in soil conditions from DS1 to DS4. Celcon Foundation Blocks can be laid below ground level without mortar perpends. Simply lay them with mortared horizontal bed joints and then butt them together to prevent the passage of vermin.

Beam and block floors

Beam and aerated block floors offer a quick, economical solution for ground and intermediate floors in homes, commercial buildings and domestic garages. Unlike timber floors, they eliminate issues such as shrinkage, flexing and squeaking. The system allows for longer spans—typically up to 6 metres—reducing the need for extensive foundations. Its fast installation provides a stable working platform, enabling early access for follow-on trades and helping accelerate the overall build programme.

What types of aerated block are available?

Celcon Blocks are designed to integrate seamlessly into standard building practices. Supplied shrink-wrapped and palletised for easy, clean storage on site, they are available in standard face sizes of 440 x 215 mm and 630 x 215 mm, aligning with conventional brick coursing for straightforward installation.

The range includes blocks in various widths and performance grades, from Celcon Standard Grade to High and Super Strength Grades, providing flexibility for different construction requirements.

Where can I buy aerated blocks?

Celcon Blocks are readily available from builders’ merchants nationwide. Look for our distinctive H+H packaging or ask in-store for Celcon Blocks.

Find further information including detailed product specifications on our product page or locate your nearest stockist at the bottom of this page.